Lunar II

Second generation compact AEK keyboard by Switchplate Peripherals and ai03

Building upon the legacy of the first generation design, Lunar II brings the acclaimed curved design to a more accessible price, complete with an entirely seamless exterior, increased typing comfort, and solenoid support.

Current Project Status: Interest Check

Undergoing revised prototype testing

| Date | Update |

|---|---|

| 2021-07-28 | Undergoing revised prototype testing |

| 2020-10-17 | Project delayed due to necessary solenoid improvements and life workload |

| 2020-09-18 | IC published at GeekHack |

A Worthy Successor

Lunar II takes user feedback into mind as it improves upon the first generation design.

The curvature has been refreshed completely to reduce the front ledge height for easier typing, and the 1.2mm aluminum plate balances typing comfort, acoustics, and ease of assembly.

A weight has been added for additional heft and aesthetic accent while retaining the low typing angle.

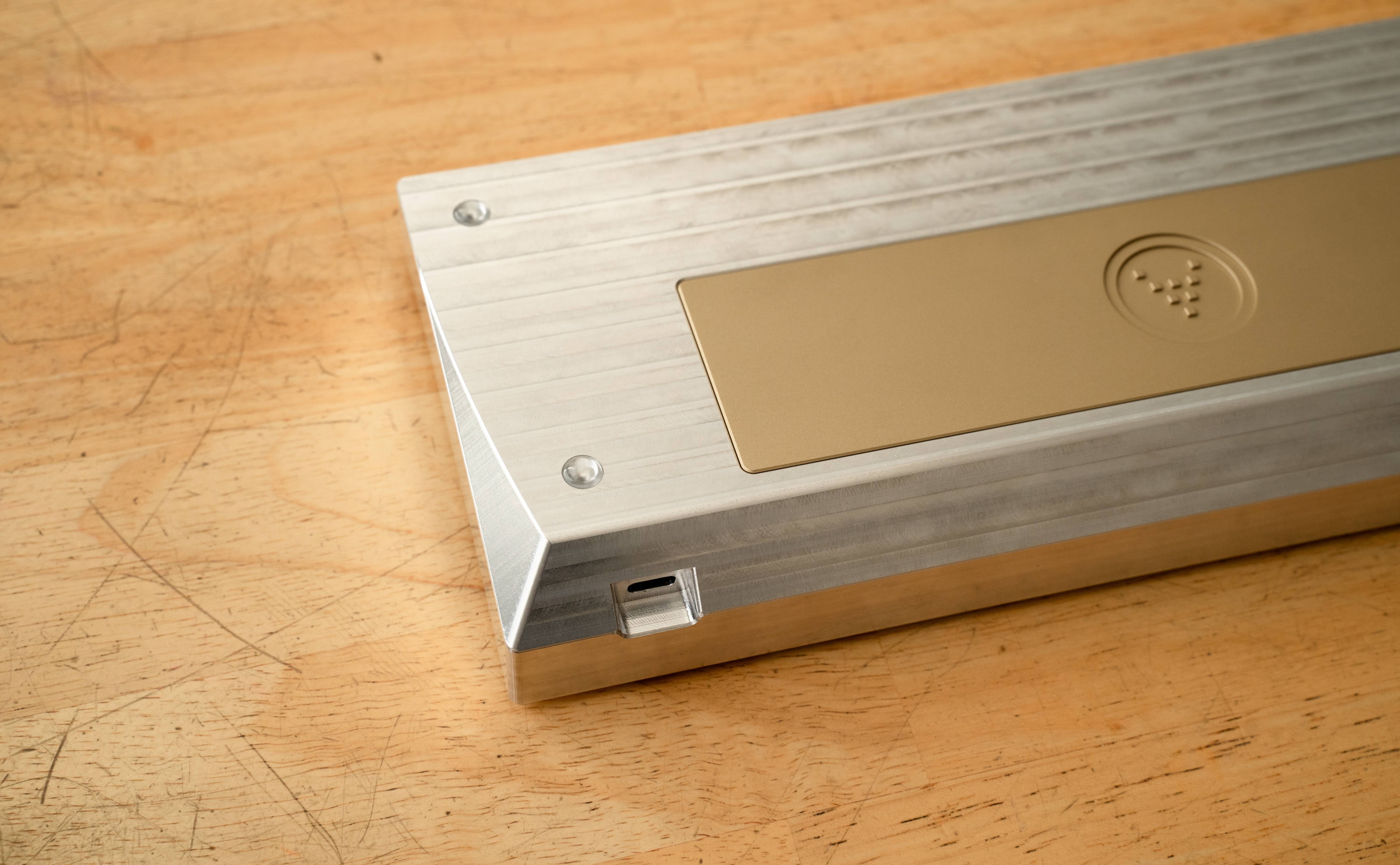

Zero-Seam Design

Whereas the original Lunar hid the seam on the bottomside, Lunar II removes the seam completely with a single-piece case, with nothing to break the continuous smooth curvature.

A carefully engineered mounting method secures the plate to the case via O-ring-tipped standoffs, allowing for maximized flex on the typing surface without the stiffness of a typical tray mount.

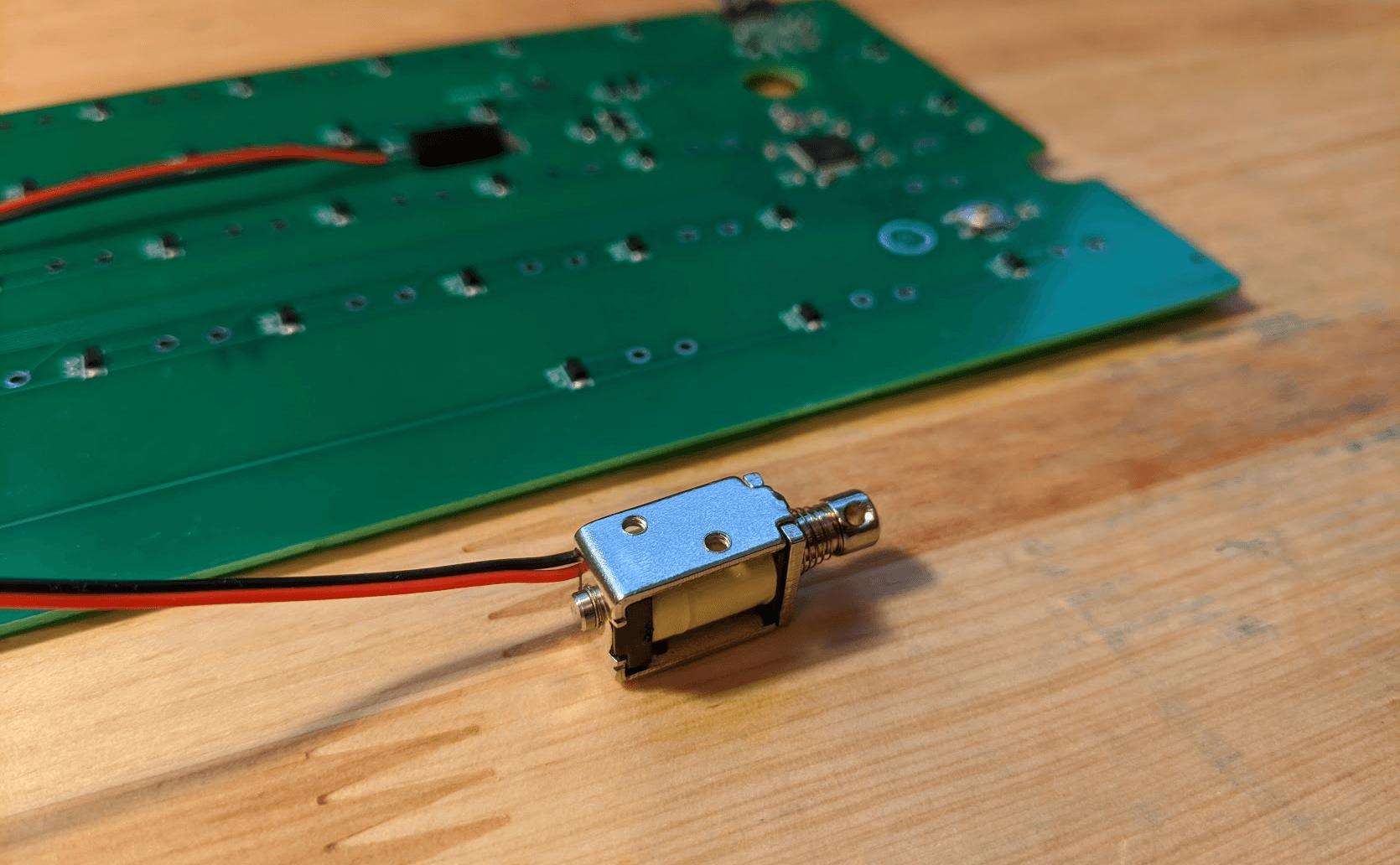

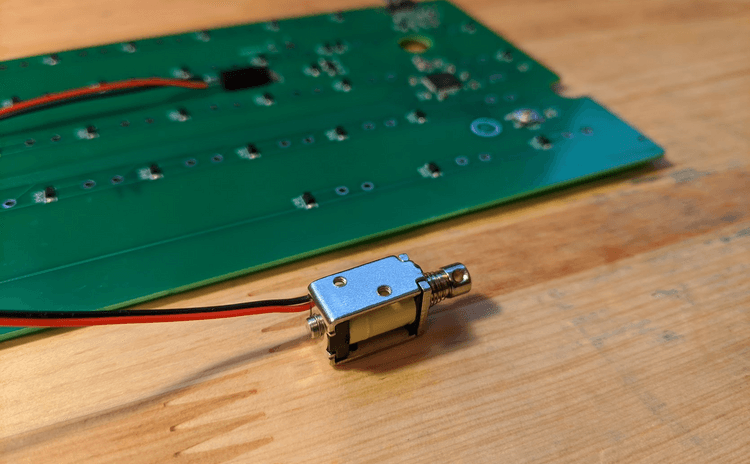

Making Noise

Solenoid support allows you to cue audible feedback at will.

Use the electromagnetic hammer to add clickiness to your favorite tactile or linear switch without changing feel, or supplement and amplify the sound of your clicky switches to a further level.

When in need of quiet, simply toggle the solenoid off.

Alps for All

The Lunar II brings the mini-AEK form to a more affordable price point with easier assembly.

Lunar II only requires a single Apple Extended Keyboard’s worth of keycaps and stabilizers to build, making the task of sourcing parts much easier than the original.

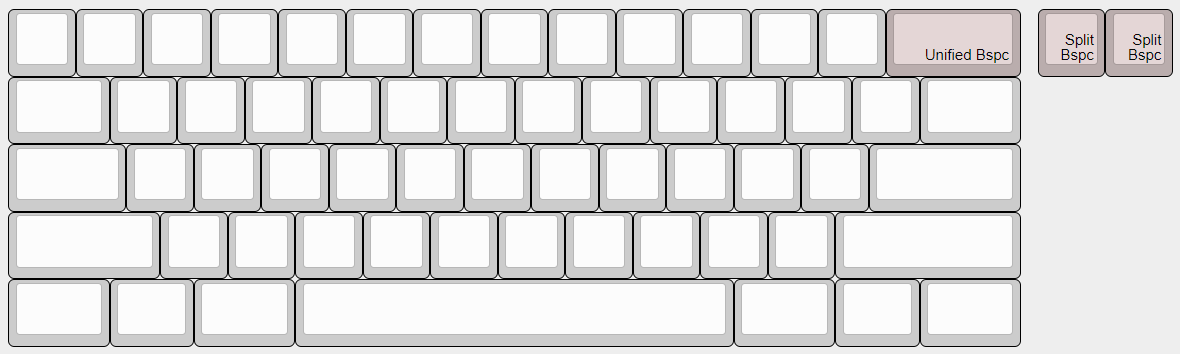

Choose between the unified and split backspace plate options to tailor the build to your needs.

Specifications

| Case | Aluminum, single part design |

| Case Colors | Silver, Grey |

| Weight | Stainless Steel planned for production units |

| Plate | Aluminum, through-PCB standoff mount, unified and split backspace variants |

| PCB | ESD protection, in-switch caps lock LED support for SKCL-LED variants, solenoid switching support (Solenoid included in kit) |

| Case Mass | ~1.2kg (Case, weight, plate) |

| Layouts | Note: Each layout requires its own plate; select the correct one as necessary.

|

| Units | Planned 100 total |

| Price | To be announced |

| Vendors | To be announced |

| Advice and Notes | Tweezers may be helpful for hooking the stabilizer wires. Prepare and test all switches before building. Solenoid installation requires slightly advanced soldering and assembly. Tweezers and soldering helping hands may be useful. The prototype case is an early unit with a brass weight; a solenoid cutout has been added in a later revision. |